Why choose molybdenum wire for wire cutting

The wire cut electrode wires have 2 types: brass wire and molybdenum wire,brass wire applies to the brass wire cutting machine(slow speed wire cut),and it can just be discharged once to process the workpiece.

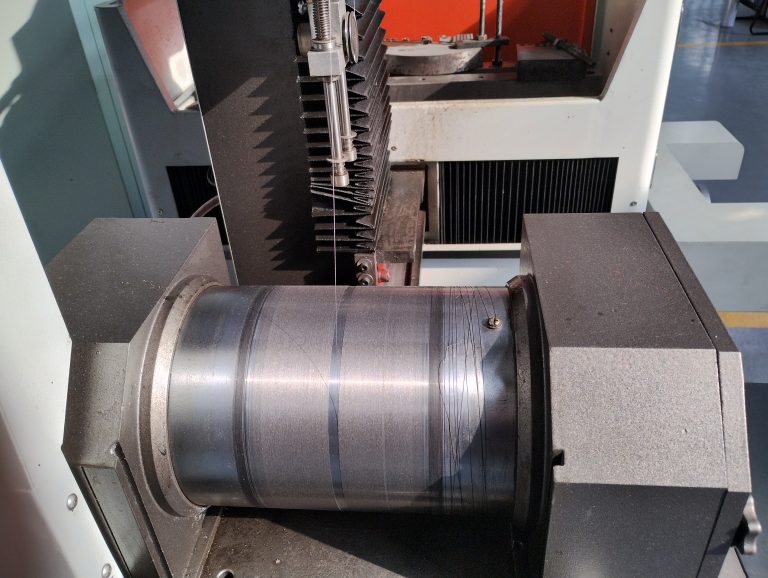

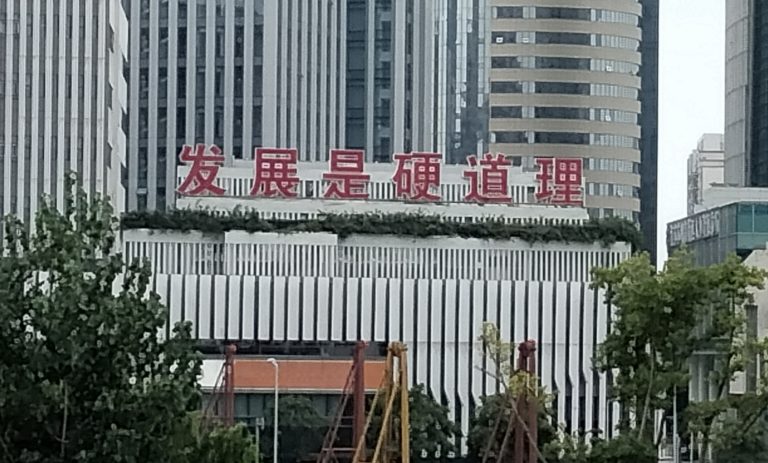

Molybdenum wire is used for the return high-speed and medium speed wire cutting machine,Those molybdenum wire can repeat discharge to cut the metal workpiece.Fast and medium wire cuts are called molybdenum wire cut together.because of the economic decoupling and blocked in west last century,the brass wire cutting machines were not allowed export to China,this unique molybdenum wire cut is manufactured independently by Chinese in 1970.As a electrode wire ,it has multiple characteristics:good electric conductivity,anti high temperature,wearing resistance,and high toughness.Let me explain them to you in details.

- The highest temperature of the working-environment is 5000 degree Celsius when the wire discharging with the work-piece.so it must be anti-high temperature,or the molybdenum wire is fusing once,the wire cutting machine will not work.

- That maximum linear velocity is 14M/S when the molybdenum wire running,The wire is threaded in the guide wheel groove and on the electric feed block made of alloy,there will be a lot of sliding friction among them.and the wire moving is repeated.molybdenum wire could be wearing resistance well for the normal working.

- The working principle of wire cutting machine is that electrode wire is discharged to the working piece to process ,not direct metal-cutting.High-frequency power supply that voltage is 70 to 110V,electric current is 0.5 to 10 Ampere needs a good conductive electrode wire,and the molybdenum wire just has this feature to work.

- Tensile strength of copper wire is 375N/mm²,but the tensile strength of molybdenum wire is 1724N/mm²,the molybdenum wire moving is repeated and discharged for long time that the wire is replaced every 7 days in general.After long time of working,the diameter of the molybdenum wire can decrease,but the tensile force on the wire is not reducing.In order to meet this processing demand,the molybdenum wire must have a good tensile properties for the wire cut edm.

Chinese engineers have upgraded the molybdenum wire production process according to the needs of wire cutting machine users in recent years, They added tungsten,cobalt,nickel and other metal to the pure molybdenum to enhance the strength of molybdenum wire,In addition,the rare earth oxides are added to the moly wire to improve the high temperature resistance and wear resistance again.The wire cutting machines are usually installed molybdenum wire from 0.12mm to 0.25mm.The D0.18mm is the most common in those.