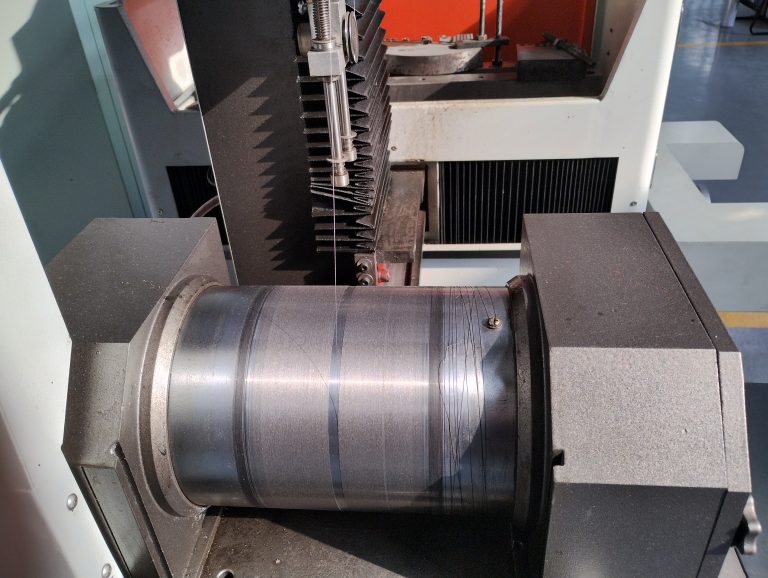

Wire edm guide wheel types and differences

The guide wheel of wire cut is very critical component that affect the working quality for machine.so wire edm users all attach great importance to these.Let’s talk about the requirements for the guide wheel assembly now.

- The guide pulley V shape groove has the characteristics of high-accuracy and wear-resistance,the radius of the V groove bottom must be less than the molybdenum wire’s radius to ensure there’s no axial motion of Mo-wire in the V groove.and most of the time,the molybdenum wire has been moving in high speed 11M/s,Therefore that is a great challenges to the wear-resistance for the guide pulley V groove.

- The mass of the guide wheel is smaller can make the inertia smaller,that reduce the slide-friction between the molybdenum-wire and guide wheel.some wire edm guide pulleys have been made of black stone to insulate and decrease the mass now.

- It is a key-step to install the guide pulley assembly with guide wheel,brass seat,bearings,screw-nuts.the quality inspection standard is that the guide wheel is rotating smooth and lightly when it sets upright.

- The lubricating grease need to be filled in between the brass seat,axis and bearings.the guide wheel assemblies will have long service life in this working environment.It is possible to cutting very large metal work-piece steadily.

Wire edm guide wheels assembly of head up and down have three structure types:

- Uni-axial bracing,installing guide wheel and molybdenum wire easily,apply to the C type medium wire cut machine.

- Double axial bracing,the guide wheel is in center,two axis are braced by double end bearings,the complex structure and hard installing wire,but good running stability and rigidity,no easy to deform and beat.longer service time.

- Double axial tip bracing,the two ends of guide wheel are 30 angle,hardness above HRC60.this structure can maintain the balance of left and right,the axial and radial run-outs≦0.004mm.but this type is prone to heat and wear.

Now,the molybdenum wire cutting machines have two types: high speed wire edm and medium wire edm,the guide pulleys are still the important parts,the size precision and service life just continuously study and optimize to improve the efficiency and reduce the production cost.