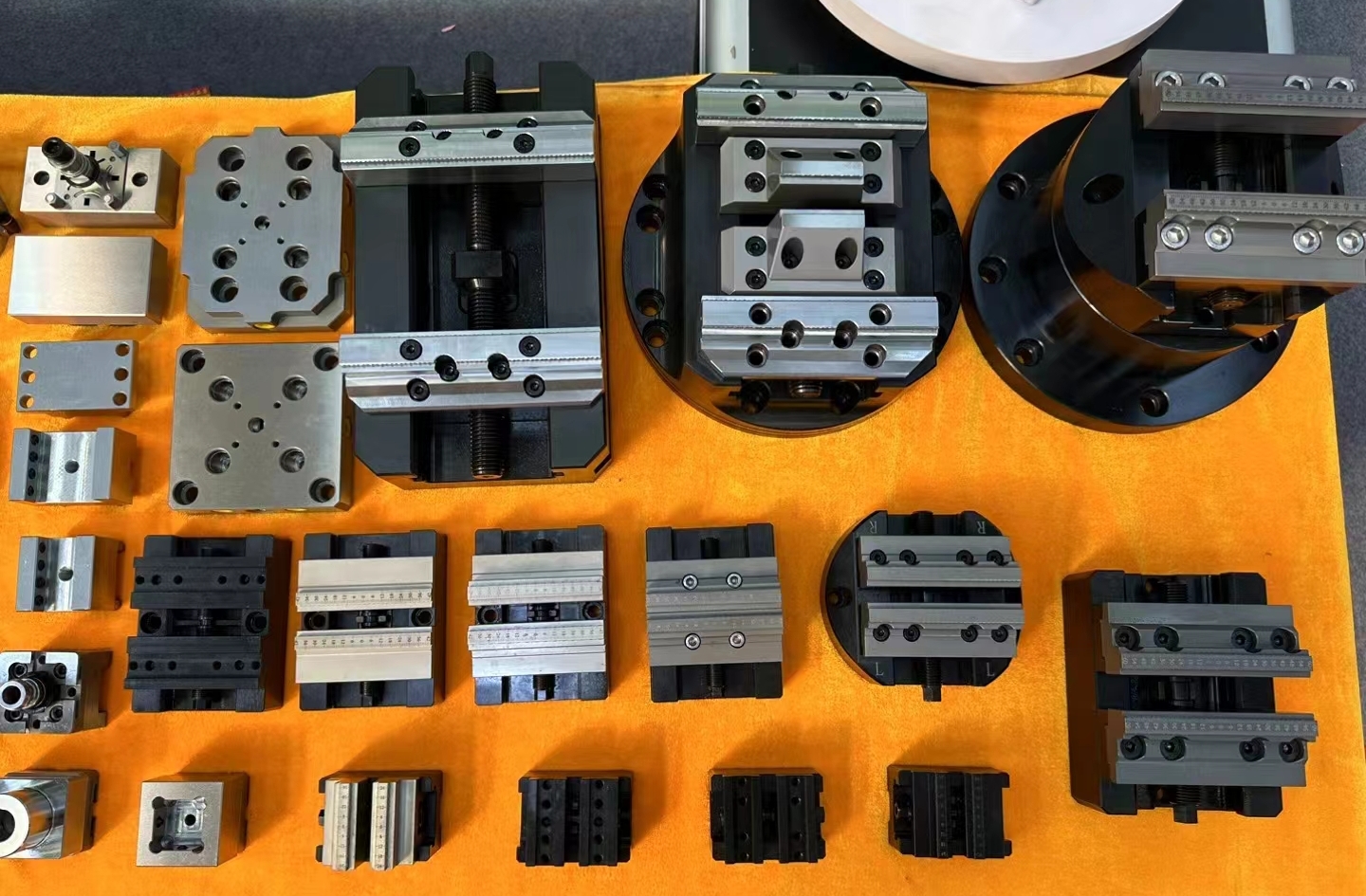

Fast replacing fixture for EDM Die Sinker

Fast replacing fixture system for the edm die sinker

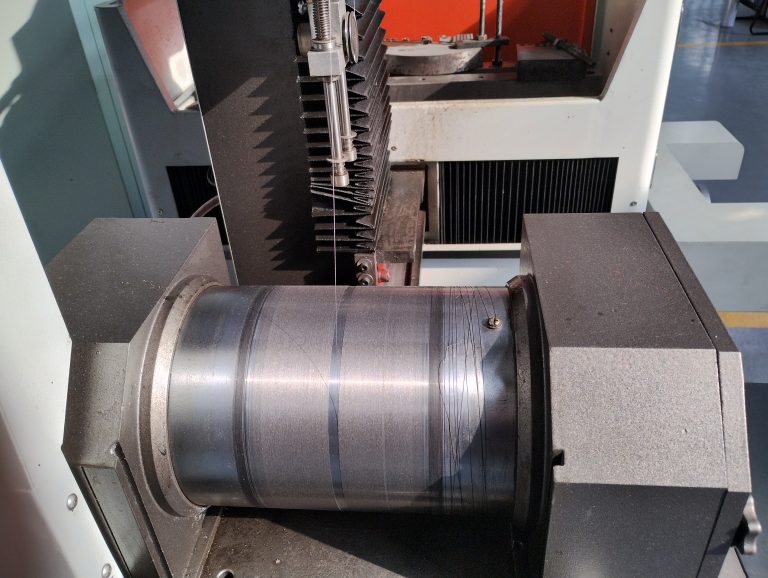

The copper electrode is the key part for the electric discharge machining,that’s used to process the mold cavity.so the quality and efficiency of producing copper electrode will affect the mold’s quality directly.

General fixture and jaw vice apply to clamp the machining electrode,that’s the traditional way. It’s 4 minutes for clamping the single electrode.and the engineers still need to spend time installing electrodes and calibrating on the edm machine.those affect the working efficiency seriously,but the fast replacing fixture can be used for clamping multiple copper electrodes one time,One a minute, it can clamp ten electrodes for ten minutes.

The characteristics of fast replacing fixture:

- precise positioning and less error,There are one mode with multiple cavities of most of the plastic molds.the precision,roughness and complexity have improved much more than before,It’s very common for multiple electrodes of the electric discharge machining at present.that’s need the less error and precision position to machine the plastic mold.

- Improving the efficiency of the edm die sinker,nc machine has processed the copper electrode in the holder,then the electrode has not taken down from the holder,that can be installed on the edm machine to work,So the fast replacing electrode holder clamp can reduce the installing electrode time,and not calibrate the position.

Time of cutting copper electrodes

| Traditional clamping | time | Fast replacing jig | time |

| Edm installing | 10 minutes | Edm installing | 5 minutes |

| Per-installation fellow up | 10 minutes | Per-installation fellow up | 10 seconds |

| Single processing | 20 minutes | Single processing | 180 minutes/9 pic |

| Per-processing | 1-4 pieces | Pre -processing | More 9 pieces |

| production | 2 electrodes/hour | production | 4 electrodes/hour |

Copper electrode discharging time

| Traditional edm | time | Fast replacing jig | time |

| Work-piece installing | 5 minutes | Work-piece installing | 5 minutes |

| Per electrode installing | 15 minutes | Per electrode installing | 10 seconds |

| Per working | 10 minutes | Per working | 10 minutes |

| production | 2 pieces/hour | production | 4 pieces/hour |

- Lower the cost,high efficiency,high quality and less error can reduce the time and labor costs effectively.two days of work in one day.the copper electrodes with holders can be used repeatedly and inspected by the three-dimensional.

The fast replacing electrode fixture system mainly apply to the CNC machining,inspection,and electric discharge machining and wire edm.used for automobile,military industry, electronics and plastic molds production.