jig selection for machine tool

How to Choose the Right Jig for Your Machine Tool: A Guide to Jig Selection

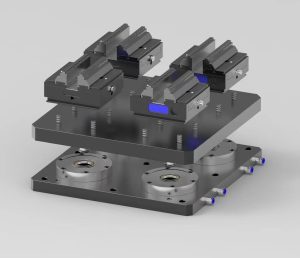

Choosing the right jig for your machine tool is an important decision that can have a significant impact on the quality and efficiency of your work. To ensure you make the best choice, it is important to understand the different types of jigs available and the advantages and disadvantages of each. This guide will provide an overview of the different types of jigs and the factors to consider when selecting the right jig for your machine tool.

The first step in selecting the right jig is to determine the type of jig that is best suited for your application. There are three main types of jigs: drill jigs, milling jigs, and grinding jigs. Drill jigs are used to guide a drill bit for precise drilling operations. Milling jigs are used to guide a milling cutter for precise cutting operations. Grinding jigs are used to guide a grinding wheel for precise grinding operations.

Once you have determined the type of jig you need, you should consider the size and shape of the jig. The size and shape of the jig should be determined based on the size and shape of the workpiece and the type of operation being performed. For example, a drill jig should be sized to fit the drill bit and the workpiece, while a milling jig should be sized to fit the milling cutter and the workpiece.

In addition to size and shape, you should also consider the material of the jig. Jigs are typically made from steel, aluminum, or plastic. Steel jigs are the most durable and are often used for heavy-duty applications. Aluminum jigs are lightweight and are often used for lighter-duty applications. Plastic jigs are the least durable but are often used for lighter-duty applications.

Finally, you should consider the cost of the jig. Jigs can range in price from a few dollars to several hundred dollars. The cost of the jig should be weighed against the quality and performance of the jig.

By considering the type, size, shape, material, and cost of the jig, you can ensure that you select the right jig for your machine tool. With the right jig, you can achieve precise and efficient results with your machine tool.

The Benefits of Using Jigs in Machine Tool Applications: Exploring the Advantages of Jig Selection

Jigs are an essential tool in machine tool applications, offering a range of advantages that make them a popular choice for many machining operations. Jigs are used to hold and guide cutting tools, allowing for precise and repeatable machining operations. They are also used to locate and secure workpieces, ensuring that the machining process is accurate and efficient. In this article, we will explore the benefits of using jigs in machine tool applications, and discuss the advantages of jig selection.

The primary benefit of using jigs in machine tool applications is accuracy. Jigs are designed to hold and guide cutting tools, allowing for precise and repeatable machining operations. This ensures that the machined parts are of the highest quality and accuracy. Additionally, jigs can be used to locate and secure workpieces, ensuring that the machining process is accurate and efficient. This reduces the risk of errors and increases the overall productivity of the machining process.

Another advantage of using jigs in machine tool applications is cost savings. Jigs are designed to be used multiple times, which reduces the need for frequent tool changes. This reduces the cost of tooling and increases the overall efficiency of the machining process. Additionally, jigs can be used to reduce the amount of time spent on setup and alignment, which can further reduce costs.

Finally, jigs can be used to increase safety in the machining process. Jigs are designed to hold and guide cutting tools, which reduces the risk of operator injury. Additionally, jigs can be used to secure workpieces, which reduces the risk of part damage or injury due to improper handling.

In conclusion, jigs are an essential tool in machine tool applications, offering a range of advantages that make them a popular choice for many machining operations. Jigs are designed to hold and guide cutting tools, allowing for precise and repeatable machining operations. They are also used to locate and secure workpieces, ensuring that the machining process is accurate and efficient. Additionally, jigs can be used to reduce costs and increase safety in the machining process. When selecting a jig for a particular application, it is important to consider the benefits of jig selection in order to maximize the efficiency and accuracy of the machining process.