How to maximize the service time of wire cut molybdenum wire

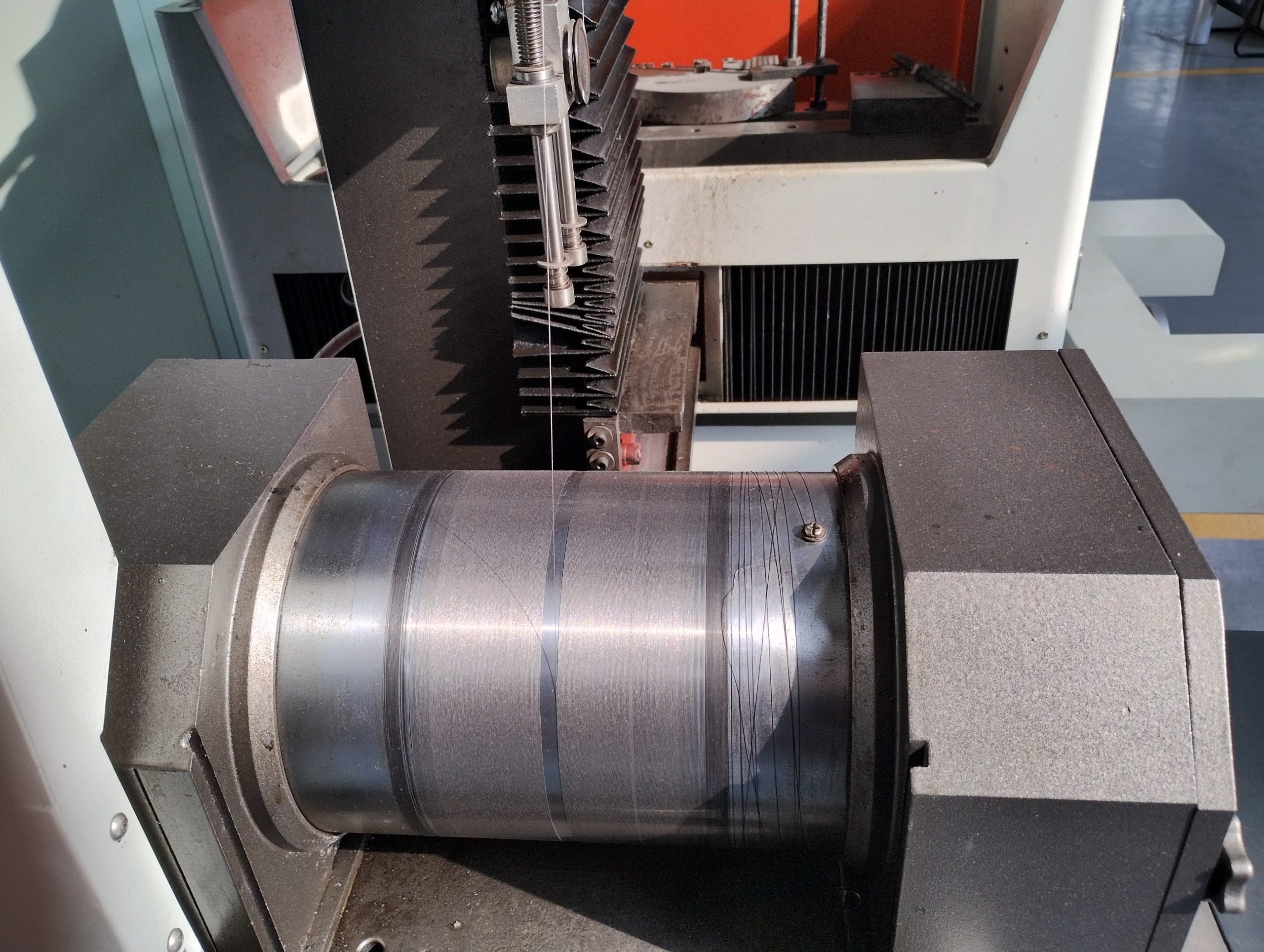

Molybdenum wire is a popular choice for wire cutting due to its high melting point and excellent electrical and thermal conductivity. However, its service life can be significantly reduced if not properly maintained. Here are some tips to help maximize the service life of molybdenum wire for wire cutting:

1. Ensure Proper Storage: Molybdenum wire should be stored in a cool, dry place away from direct sunlight and other sources of heat. It should also be kept away from corrosive materials and chemicals.

2. Use the Right wire running Speed and feed rate: The cutting speed should be adjusted according to the material being cut. the wire running speed is 4 to 11m/s,the temperature of the working center area between molybdenum wire and workpiece is 5000 degree celsius,Therefore,the lower the wire running speed ,the more the loss of molybdenum wire,the feed rate must be less than the material eroded rate,or the running wire will contact the workpiece that make the wire wear out.

3. Set the Right machining current: the values of machining current are related to the materials and thickness.when the thickness and materials are sured,Too high machining current can cause the wire to overheat and break.

4. Use the Right Cutting Fluid: The cutting fluid should be chosen according to the material being cut.and must be replaced every 15 to 30 days generally,The expired cutting fluid can cause the wire to overheat and break.

5. Replace the wire guide wheel and conductive block regularly: the guide wheel has been damaged that cause the wire to vibrate more,the conductive blocks create friction with the molybdenum wire during the machining process,The conductive blocks need be cleaned regularly to remove any debris or buildup that can cause the wire to overheat and break,if there is a deep narrow slit in the conductive block that make the wire break,customers have to replace the conductive block.high quality guide wheel proof water youtube video

6. Inspect the Wire Regularly: The wire should be inspected regularly for signs of wear or damage. the operator can measure the wire diameter with a micrometer,Any damaged or worn wire should be replaced immediately.

By following these tips, you can help maximize the service life of molybdenum wire for wire cutting. Proper maintenance and care of the wire will ensure that it lasts longer and performs better.