wire edm machine guide wheel benefits

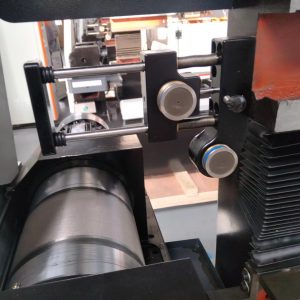

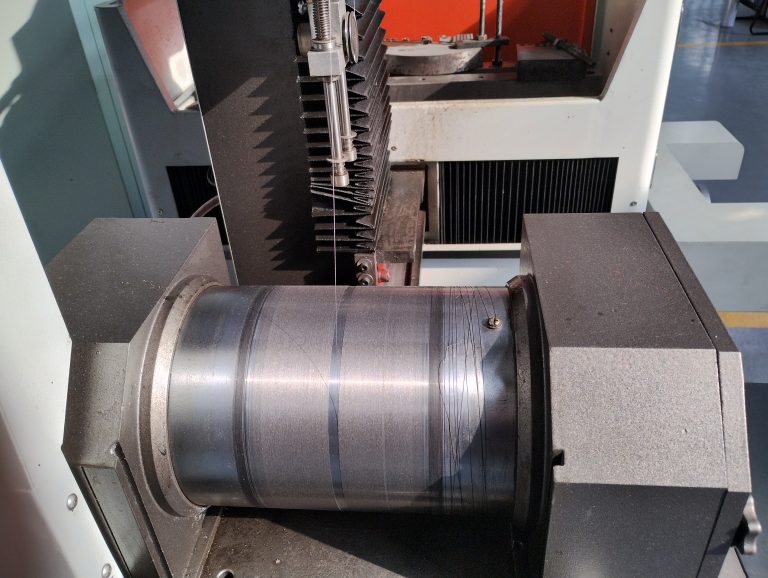

guide wheel is one crucial component of edm wire cut machine , which helps to guide the wire through the workpiece. There are several usages of guide wheel of EDM wire cut machine in precision machining.

One of the primary advantages of using a guide wheel in wire EDM machining is improved accuracy. The guide wheel of edm wire cut helps to ensure that the wire stays on track and cuts through the workpiece with precision. This is especially important when working on intricate or complex parts that require tight tolerances. By using a guide wheel, machinists can achieve higher levels of accuracy and produce parts that meet the most demanding specifications.

In addition to improved accuracy, using a guide wheel in wire EDM machining can also help to increase productivity. The guide wheel allows for faster cutting speeds and reduces the risk of wire breakage, resulting in shorter machining times and higher throughput. This is particularly beneficial for manufacturers who need to produce large quantities of parts quickly and efficiently.

Another benefit of using a guide wheel in wire EDM machining is reduced wear on the wire. The guide wheel helps to support the wire and prevent it from bending or vibrating excessively during the cutting process. This reduces the risk of wire breakage and prolongs the life of the wire, saving time and money on replacement costs. Additionally, by reducing wear on the wire, the guide wheel helps to maintain consistent cutting performance and ensure high-quality results.

wire edm machine guide wheels can also help to improve surface finish quality. The guide wheel helps to stabilize the wire and minimize vibrations, resulting in smoother cuts and finer surface finishes. This is particularly important for parts that require a high level of precision and a flawless appearance. By using a guide wheel, machinists can achieve superior surface finishes and produce parts that meet the highest aesthetic standards.theguide wheel bottom arc radius of V groove R < 0.005mm,the bottom diameter of V groove, Conical surface and tail pulley shaft to axis of the round beating<0.005mm.

Overall, the benefits of using a guide wheel in wire EDM machining are clear. From improved accuracy and productivity to reduced wear on the wire and enhanced surface finish quality, the guide wheel plays a crucial role in achieving high-quality results in precision machining. By incorporating a guide wheel into their wire EDM machines, manufacturers can optimize their machining processes and produce parts that meet the most stringent requirements.

The edm wire cut guide wheel is an essential component of a wire EDM machine that offers a wide range of benefits in precision machining. By using a guide wheel, machinists can achieve higher levels of accuracy, increase productivity, reduce wear on the wire, and improve surface finish quality. Overall, the guide wheel plays a crucial role in optimizing wire EDM machining processes and producing high-quality parts that meet the most demanding specifications.