Evolution of molybdenum wire cutting

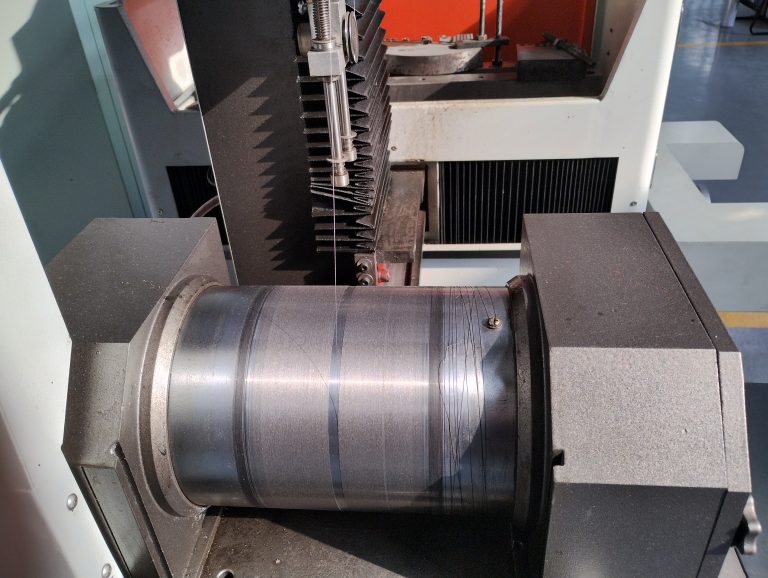

Molybdenum wire cutting machine is a Electric discharge machining by molybdenum electrode wire.That has some advantages of low power and cost,high-speed efficiency and easy operation.we also call it high-speed wire cut or medium wire cut edm now.

In the 1960s,the United States led the Western countries imposed an economic and technological blockade on China.Chinese enterprises could not import the advanced brass wire cutting machine(slow wire cutting) made from western countries and Japan,but the Chinese engineers developed the high-speed wire cut machine(HSWEDM) independently.That’s machining accuracy and efficiency lagged behind the brass wire cut machine though,it could meet the needs of the customers basically.The first generation high speed wire cut use the molybdenum wire as the electrode wire,which can repeated moving to work. The worktable travel: 80×100mm,max thickness cutting:20mm,shape accuracy:≦0.015mm.cutting speed:30mm²/min

In the 1980s and 1990s,China started to reform and open up,the economic had developed rapidly.Market demand of molybdenum wire cut machine increased.wire cutting machine had a great development on quality and technology during this period.The max.travel:1000×1200mm,Thickness:500mm,max.cutting speed: 80mm²/min.Roughness:≦2.5um

Enter the 21st century,more private enterprises joined the wire cut industry, the excellent engineers and operators learned from the multi-cut technology of brass wire cutting(SWEDM) to manufacture the multi-cut molybdenum wire cutting,and advances have been made in the precison screw,driving motor,guide pulley assembly,So this machine had a great change, we called it medium wire cutting.The work-piece had a better surface roughness and accuracy than before,and the working solution had large progress,appearance of the machine had improved greatly,which made the working environment better.

Max.travel:1500×2000mm,Thickness:1200mm,shape accuracy ≦0.001mm,max.speed:220mm²/min,Roughness:≦1.0um

There is still a gap in accuracy and roughness between medium wire cutting and slow wire cutting,but the many of the metal work-pieces and molds could not need so good accuracy and roughness,the molybdenum wire can be repeated using for a long time,which means lower cost,Medium wire cutting still has a board market demand. The manufactures around the whole world are more aware of Chinese molybdenum wire cutting machine values